Strain Gauges vs Distributed Fiber Optic Sensing, Part 2 of 3: Sensitivity and Setup

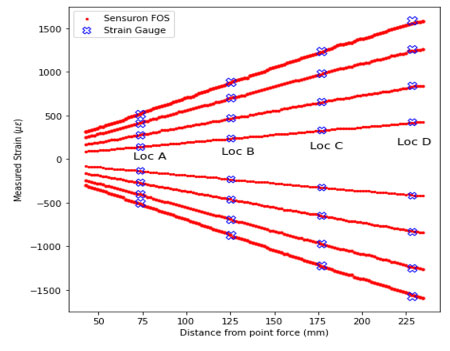

Fiber Optic Strain Sensitivity The two direct measurements of all Sensuron interrogators are mechanical strain and temperature. This is due to the inherent sensitivity of the Bragg wavelength, as seen below in the well-known Bragg equation. In the absence of thermal effects, obtaining the strain from the above equation is very straight forward. The temperature […]

Strain Gauges vs Distributed Fiber Optic Sensing, Part 2 of 3: Sensitivity and Setup Read More »