White Papers

Sensuron’s compact fiber sensing systems are being used across multiple industries to provide next-generation solutions to complex applications.

You’re welcome to download any of the white papers listed below by visiting our Downloads page.

Strain Measurements Comparison - Fiber Optics Sensing vs. Strain Gauges

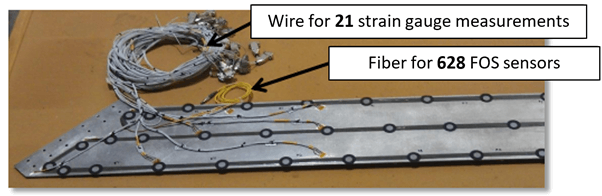

Fiber Optic Sensing (FOS) systems have an intrinsic advantage over traditional Strain Gauge (SG) technology, namely they are capable of measuring strain along the sensing fiber in multiple locations.

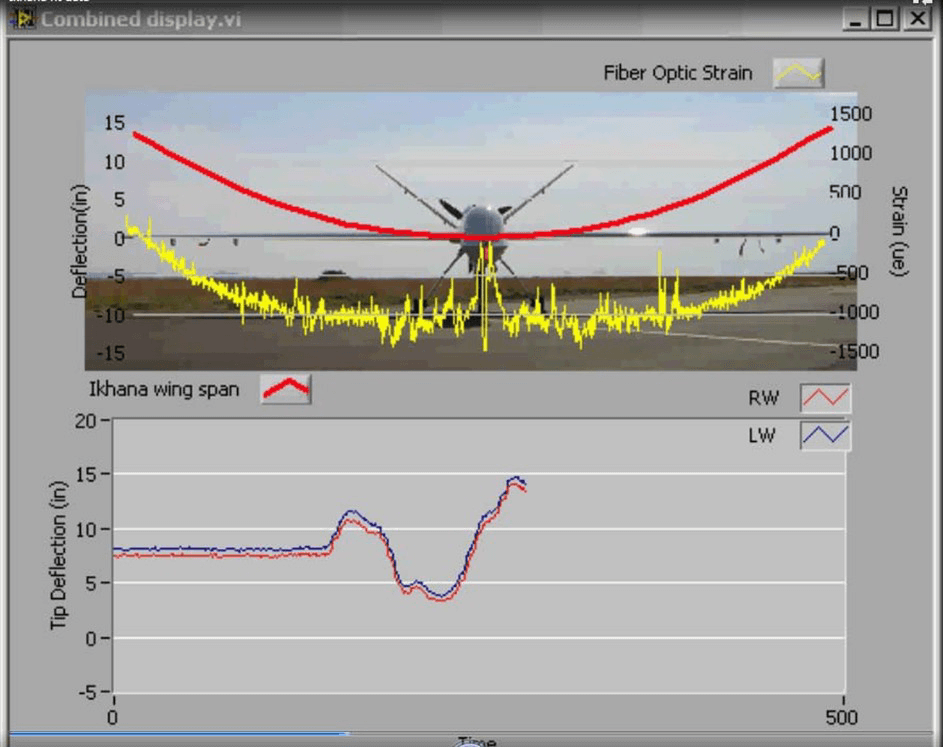

Sensuron’s FOS system developed in collaboration with NASA is capable of measuring strain at over 2000 locations along a 13m fiber. A single fiber that provides a high-density strain profile along its length can replace tens or hundreds of strain gauges depending on the length of the fiber.

For instance, 2000 SG are required to replace a 13m sensing fiber. However, fiber instrumentation is a topic that can benefit from the vast body of knowledge and experience in SG installation technology.

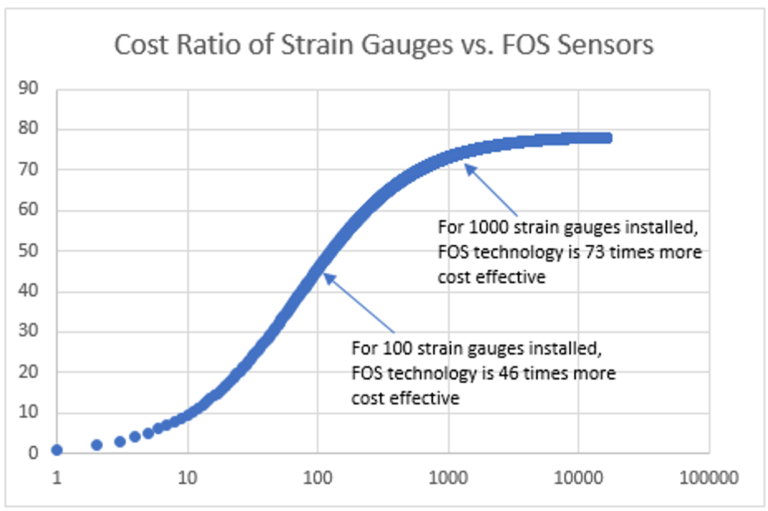

Fiber Optic Sensing vs. Strain Gauges – Cost Analysis Study

Fiber optics sensing technology enables a paradigm shift to take place in the area of structural testing, specifically for strain and temperature sensing.

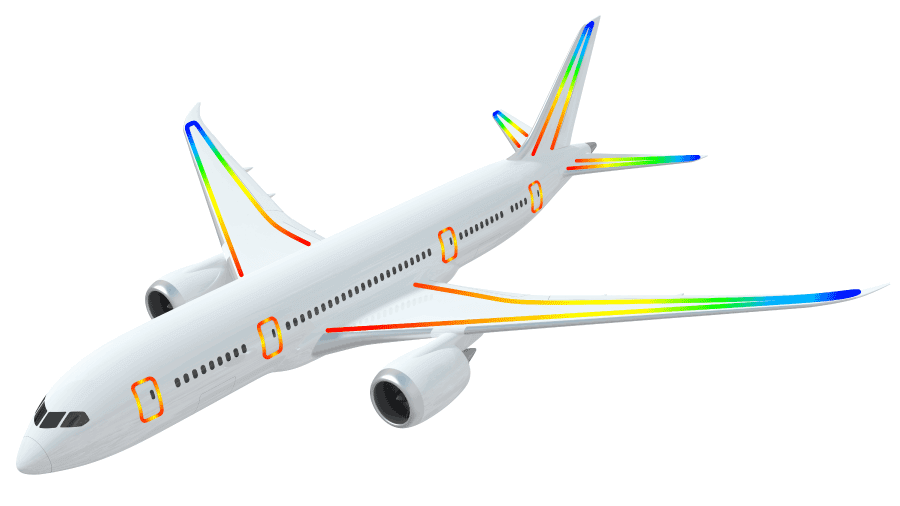

Spatially continuous measurements along the length of thin, flexible, and virtually weightless optical fiber make it possible to develop a new set of tools that provide deeper insights into how materials react to both strain and temperature.

One great example of this is the structural testing of full-scale aerospace structures. Thousands of fiber optic strain gauges can be installed on an aircraft in a fraction of the time required to install traditional strain gauges, making it economically feasible to collect strain measurements at thousands of sensing points.

Introduction to Fiber Optic Sensing

Fiber optic sensing is becoming pervasive across multiple industries including manufacturing, medical, aerospace, automotive, civil and energy.

Within the market, there are dozens of types of technology, each with their own capabilities. Navigating the fiber optic sensing landscape can be challenging due to the variety of technologies. This guide is intended to provide a framework for understanding fiber optic sensing technologies and to provide insights into the direction of the market.

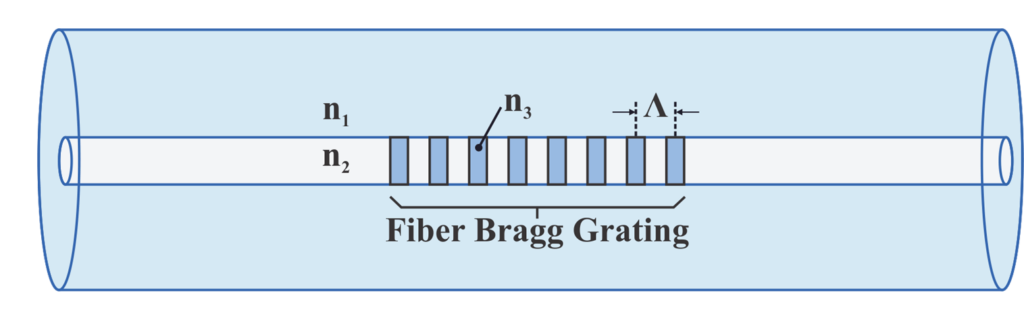

Fiber Optics Sensing Fundamentals

Fiber optic sensors offer several unique advantages over conventional electrical based sensors.

These advantages include immunity to electromagnetic interference, being extremely lightweight and small, embeddability, and excellent fatigue life.

The most significant advantage of the Sensuron technology is the ability to acquire spatially continuous information along the entire length of an optical fiber with only a single lead cable.

Single point measurement devices, such as a strain gauge, only capture information at a discrete point while requiring multiple lead cables and hours to perform an installation.

A single fiber spanning upwards of 10 m, in contrast, can act akin to thousands of strain gauges or thermocouples installed adjacent to one another without the cumbersome associated wire bundles.

For these reasons, fiber optic sensors are employed in wide variety of industries including civil, mechanical, aerospace, medical, energy, and automotive.

Distributed Strain and Temperature Measurement

For decades, point sensing solutions like strain gauges and thermocouples have been good enough for most applications of strain and temperature measurement. However, the mindset of ‘good enough’ often blocks innovation.

New, robust sensing technologies that can monitor beyond the scope of point sensors are necessary to enable the next generation of designs.

Fiber optic sensing platforms that obtain spatially continuous, real time data and can sense multiple parameters simultaneously can accelerate product innovation through easier installation, collecting more comprehensive data, combining multiple sensing capabilities into a single platform, and more.

Distributed Fiber Optic Temperature Sensing

Temperature is the most measured physical parameter in the world. For many industrial and commercial processes, temperature monitoring is essential to ensure operational safety and efficacy.

Conventional electric temperature sensors prevalent throughout industry can perform adequately if they are replaced often and are effectively shielded from EMI.

However, they all suffer from the same inherent limitation: they can only measure temperature at a single point or location.

In practice, these sensors are often deployed at only a handful of locations and thus the overall temperature distribution remains unknown.

The intent of this document is to present fundamentally how to perform distributed temperature sensing and demonstrate achievable accuracies with empirical results.

If the reader is unfamiliar with the underlying principles behind fiber optics and the Sensuron interrogators, our white paper on Fiber Optic Sensing Fundamentals is a recommended precursor to this document.

Strain measurements using Fiber Optics Sensing

For over eight decades the resistive strain gage (RSG) has been the benchmark for measuring structural deformation.

RSG applications are well known and their limitations have long been established.

Now, distributed strain and temperature sensing technology allows users to improve accuracy and address various known RSG limitations while opening up yet unrealized possibilities to better design, test, and field products and applications.

These improvements will result in safer, better performing, and more cost-effective products and services.

Fiber Installation Methods for High-Resolution FOS

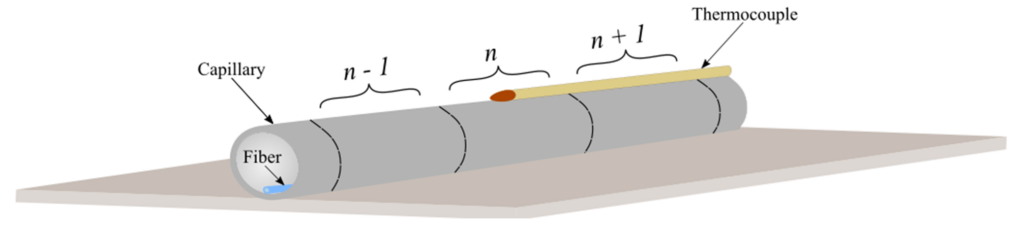

Fiber Optic Sensing (FOS) systems have been in use for over three decades but there is still some confusion about the best installation methods. Sensuron’s FOS provides hundreds to thousands of sensing points with a resolution of 1.6 to 6.4mm along a single sensing fiber.

To obtain accurate strain measurements, proper fiber installation is a must. At Sensuron we’ve had the opportunity to be involved with projects that require a wide range of installation methods.

This paper provides a review of the installation methods that we’ve had hands-on experience with, focusing on surface installation using adhesives, surface installation using tape, fiber embedment in concrete, and fiber embedment in composite materials.