Sensuron’s fully distributed fiber optic sensing technology enables a paradigm shift to take place in the areas of structural testing and monitoring.

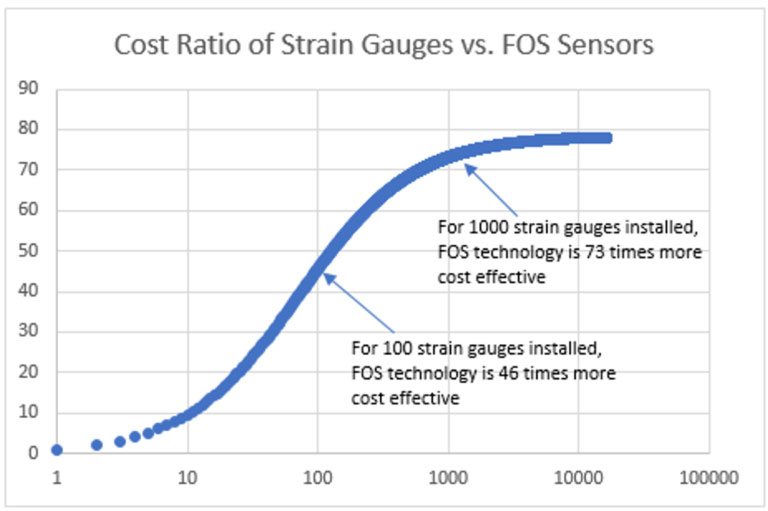

One frequently overlooked aspect of this shift is the potential cost savings when compared with the use of traditional sensors. For example, thousands of fiber optic strain gauges can be installed on an aircraft in a fraction of the time required to install traditional strain gauges.

Due to the laborious nature of the installation process, strain gauges are often deployed in limited numbers at probable critical points throughout a structure. Fiber optic sensors are installed using similar methods, but at a significantly faster pace.

For the same amount of labor required to install two quarter bridge strain gauges, approximately 85 fiber optic strain gauges can be installed.

Thom Rollins, a principal engineer at Northop Grumman said it best: “ A single fiber allows us to replace thousands of strain gauges, saving significant man-hours of effort on a single project and providing us with new insight we would not have gotten using legacy sensing technology”.

For applications that require or can benefit from the use of multiple strain sensors, the cost effectiveness and reduced installation time of fiber optic sensing technology is clearly attractive.

This is demonstrated in much greater detail in a white paper available on our website titled Fiber Optic Sensing vs Strain Gauges.