Case Studies

Sensuron’s distributed strain and temperature sensing systems have been used to test, measure, and improve use cases for applications across the aerospace, medical, automotive, energy, and civil engineering fields.

Learn more about how our technology can solve problems in your industry.

You’re welcome to download any of the case studies listed below by visiting our Downloads page.

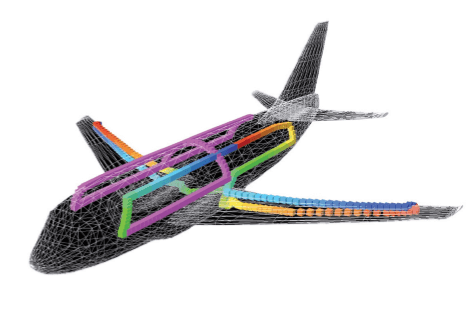

Sensuron Technology Onboard NASA’s X-56 UAV

The subscale X-56 UAV is the latest aircraft at NASA Armstrong to be instrumented with FOS technology.

NASA is using FOS to investigate challenges associated with highly flexible, lightweight wings.

In contrast to stiff, rigid wings found on commercial aircraft today, X-56 is outfitted with long, very high-aspect ratio wings which often flex significantly during flight.

The use of more flexible wings is considered essential to next generation, fuel efficient aircraft. Commercial aircraft currently do not employ wings of this nature due to their susceptibility to the highly destructive aeroelastic instability known as flutter.

NASA is utilizing FOS data to identify the onset of flutter and drive active flutter suppression systems.

2D Shape Sensing of Bored Tunnel Soil Settlement

Sensuron technology was recently utilized to measure the settling movement related to a metro boring project in Beijing, China.

A 2D sensor was placed in a reduced scale boring test setup to measure the soil displacement resulting from a simulated excavation process.

The existing methods of Digital Image Correlation (DIC) and electronic-based displacement sensors, due to their inherent limitations, were unable to produce the desired measurements within the test volume.

The fiber-based 2D shape sensor acquired an accurate soil displacement distribution along a continuous line of the surrounding soil and provided sub-millimeter validation of their settling models.

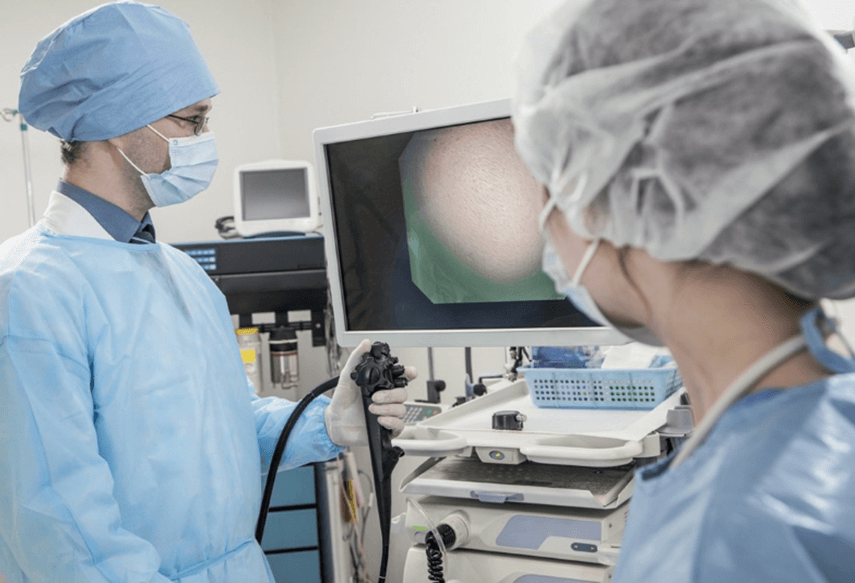

3D Fiber Optic Shape Sensing for Medical Applications

Improving medical techniques while also driving down costs and reducing risks are all key metrics in the testing and adoption of new medical technologies.

This is exactly what is attractive about medical instruments equipped with optical 3D shape sensors. For minimally invasive surgical procedures, 3D shape sensors enable higher- resolution instrument tracking while minimizing the complexity associated with traditional ultrasonic and fluoroscopic methods.

This equates to reduced risk of complication during procedures, quicker recovery, and thus better long-term health for patients.

Fiber Optic Sensing for Nondestructive Evaluation

One major challenge facing the development of prominent nondestructive damage evaluation (NDE) tools has been a lack of fine spatial resolution from sensors.

Advanced distributed sensing platforms resolve this issue with spatial resolution down to 1.66mm. In short, the technique uses pre- and post-damage ambient strain measurements collected from a relatively dense sensor layout provided by the fiber optic sensing platform to:

- Detect the existence of damage.

- Determine the location of damage.

- Quantify the severity of damage with very high accuracy irrespective of the size of the inflicted damage.

Deflection Sensing for Structural Health Monitoring

Structural Health Monitoring (SHM) is an essential branch of engineering science focused on the surveillance of structural behavior.

SHM is implemented to detect, locate, qualify, quantify, and prevent various types of material damage. As the nation’s infrastructure ages and air and space vehicles grow ever more complex, SHM systems and algorithms must be increasingly comprehensive, robust, and reliable.

Distributed strain sensing (FOS) systems, based on coherent Optical Frequency Domain Reflectometry (OFDR), are poised to dramatically improve upon current SHM technologies through unparalleled measurement capabilities and exclusive two-dimensional (2D) deflection sensing algorithms.

Capabilities for Structural Analysis

Understanding how engineering structures respond to loads and their environment is of paramount importance for their successful design and reliable operation.

Analyzing the strains, stresses, temperatures, and deflections in a bridge during rush hour, a composite aircraft’s wing spar during a storm, or a high-end bicycle during the Tour de France is what allows engineers to predict a structure’s lifetime, increase its safety, and optimize its performance.

Armed with a complete picture of these quantities from the early design stages to the end of a product’s lifecycle, designers would undoubtedly create safer, stronger, and more efficient engineering structures.

Now there is a distributed sensing platform capable of providing this information in real time, monitoring strains, temperatures, stresses, out of plane deflections, and three dimensional shape using a small and lightweight package.

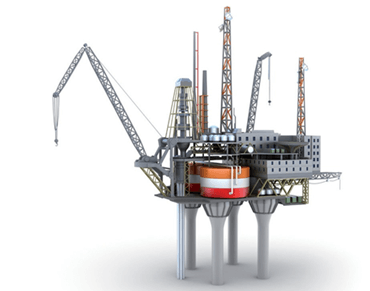

Subsea Riser Monitoring Using Optical Sensing

Subsea applications such as riser monitoring have long used engineering techniques and practices taken from the space flight and aerospace engineering domains.

Both disciplines deal with high-value, mission-critical components and systems where failure is not an option. For this reason, risk management dominates all other factors when designing components and operating systems.

As the aerospace community has known for years, effective risk management is made possible by collecting more of the right data.

Distributed fiber optic sensing systems, which have been deployed in both space flight and aerospace applications, are also ideally suited for Subsea Riser Monitoring because they enable the advanced collection of real-time tension, torsion, and shape information.