COVERAGE

Using Fiber Optics for the Next Generation of Sensors

02/09/2016 By Megan Crouse, Real-Time Digital Reporter, Product Design & Development @abmdigi

Fiber optic sensors can provide many more points of data than conventional sensors, including deflection. Sensuron, an Austin, Texas based company which celebrates its one-year anniversary this month, talked to PD&D about how sensor development is changing and the philosophy behind their niche in the industry.

As stated on their website, Sensuron was spun out of 4DSP in February of 2015. At the year anniversary, they’re working on improving the sensitivity of fiber optic sensors and find new ways to use them.

When 4DSP began as a board-level and system-level electronics company almost a decade ago, they observed that products were developing faster than the ability to test them. Devices like strain gauges and accelerometers were significantly older than the machinery they were testing, and were reaching their limits.

In order to avoid that, Sensuron does work inspired by the necessity of forward motion. Sensuron CEO Michael Heflin explained some of the ideas behind the company in February, after they were first brought to our attention at Embedded Tech Trends in January.

“What people continuously find is that they reach a point where they have innovated beyond what they test. It takes a significant failure for them to say, or us to admit, that this is a human issue, not a hardware issue,” Heflin said.

This, Heflin said, is the primary reason people come to Sensuron – they stop thinking what they have is good enough.

And fiber optics, Heflin said, helps them keep up.

Thousands of sensors can be housed on a single fiber, allowing for more data points and more possible types of readings. In particular, Sensuron and their partners at NASA Armstrong use fiber Bragg gratings, which are placed along the length of the fiber.

“We’re able to read each of those reflected light signals and differentiate one after another and be able to understand two things: strain and temperature values,” Heflin said. By determining those, they can find out many other things, including how much liquid is in a fuel tank based on the different thermal properties between liquid and air. Some users put coatings on the fiber that react to different environmental elements, such as magnetism or chemical reactions.

This is advantageous because it could take months to lay out one hundred or one thousand strain guages. With Sensuron’s technology, over a thousand could be set up in a day.

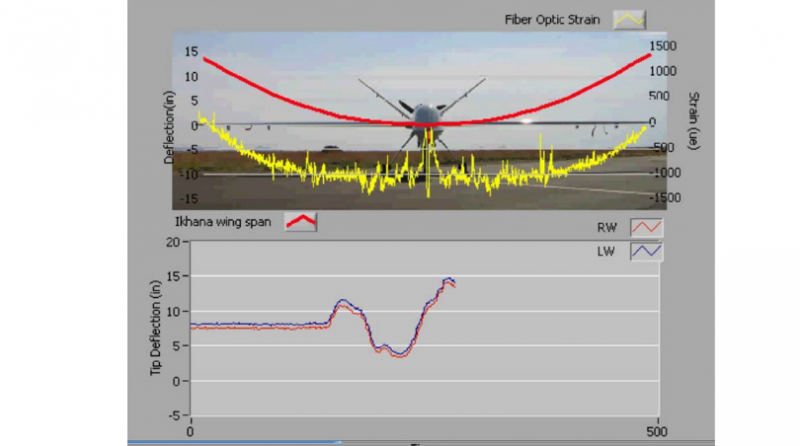

In aviation, aircraft wings can be threaded with sensors in order to monitor structural health, strain, or other measurements. Fiber optic sensors can also measure deflection, the three-dimensional shape of the fiber, which is particularly useful in medical applications or other structures that bend.

Sensuron partnered with NASA’s Armstrong Flight Research Center last year on a ruggedized fiber optic sensing system that could read up to 2,000 data points and may be used on a launch vehicle. Backed by NASA algorithms, the sensing system helped Sensuron become a finalist in the 2015 R&D 100 Awards.

NASA used fiber Bragg gratings for testing since about 2008, including on the wings of unmanned vehicles.

Sensuron uses a generation of fiber optics called optical frequency domain reflectometry, in which the entire length of the fiber is packed with sensor after sensor.

Heflin said that, more and more, people in his field are looking at technology that can enable composite fibers to be embedded in the wings or fuselage of an aircraft, as well as other critical zones such as landing gear. The company’s sensors are also applied on or in composite fibers, which may lose integrity when used on aircraft depending on what adhesives are used or what temperature the fibers need to endure. Stringing them with fiber optic sensors can help examine what causes imperfections.

Since their inception, Sensuron has been working on enabling the testing that enables new development. One thing that Heflin called “a huge challenge” is the ability to measure the amount of fuel in a fuel tank in zero gravity. The work that’s being done on this is still under lock and key, but Heflin said it’s one of the forward-looking areas in which Sensuron is working.