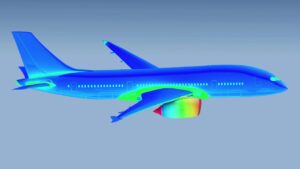

In the world of aerospace, precision and reliability are not just desired; they are crucial. Every component, from engine parts to avionics, must function seamlessly under extreme conditions to ensure the safety of the crew and passengers. With the ever-evolving demands of the industry, it’s essential to have cutting-edge instruments that monitor and safeguard the integrity of these critical systems. The aerospace sector is increasingly relying on technology to push the boundaries of performance, and one such innovation is the use of advanced sensing systems. But how can we ensure that every component is functioning within safe parameters?

At Sensuron, we understand the importance of continuous monitoring in preventing failures before they happen. To address this challenge, we utilize Distributed Temperature Sensing (DTS), a technology that allows us to monitor temperature variations over distances up to 104 meters. This system provides real-time, precise temperature data from any point along the length of an optical fiber, enabling us to detect temperature anomalies that could signal impending failures. Aerospace components, subject to intense stresses and environmental conditions, can greatly benefit from this high-resolution monitoring, which ensures optimal performance and safety.

How Distributed Temperature Sensing Ensures Safety in Aerospace Components

Continuous Monitoring

Traditional sensors can miss critical temperature variations along a component. Our system uses a single optical fiber to monitor temperature across a distance of up to 13m per fiber. This allows us to detect temperature changes in turbine blades or fuselages, ensuring thorough monitoring and the prevention of unnoticed issues.

Real-Time Data for Immediate Action

In aerospace, delays in detecting issues can lead to severe consequences. Our system provides real-time temperature data, allowing engineers and maintenance teams to respond immediately. By comparing current temperatures with historical data, we can identify unusual patterns early, helping prevent downtime and costly repairs.

Enhanced Durability in Harsh Environments

Aerospace components face extreme conditions that can cause wide temperature fluctuations, leading to wear and mechanical failure. Our system monitors these fluctuations across components, identifying temperature deviations early. This early detection allows for timely interventions, prolonging the life of critical parts and enhancing their durability.

Reduction of Maintenance Costs and Downtime

Our continuous, non-invasive monitoring reduces the need for frequent physical inspections, saving time and costs. Maintenance teams can quickly identify potential issues without disassembling components. This leads to fewer maintenance events, lower repair costs, and less downtime, resulting in more efficient operations and reduced operational costs.

In conclusion, Sensuron’s Distributed Temperature Sensing system provides aerospace engineers with an invaluable tool for maintaining the safety and performance of critical components. Our advanced technology ensures that temperature variations are detected early, allowing for prompt action that prevents failures and enhances the longevity of aerospace systems. Through real-time monitoring, high resolution and broad coverage, DTS is an essential part of the aerospace industry’s push toward higher safety standards and optimal performance.