The medium used for strain gauges is typically a metal alloy connected to a few copper wires. The same type of technology enabled telephone networks to connect the world starting in the second half of the 19th century.

At the advent of the internet, copper became a bottleneck to transmit data, as those of you who remember dial up internet will remember.

Fiber optics made it possible to start streaming information across significantly longer distances at bandwidth levels orders of magnitude higher than any copper transmission line.

Because of the sheer amount of data that can be sent using fiber optics, an entire new set of applications and services became available to users, such as high speed video streaming.

Similarly, Sensuron’s fiber optic sensing technology enables a paradigm shift to take place in the area of structural testing, specifically for strain and temperature sensing.

Spatially continuous measurements along the length of thin, flexible, and virtually weightless optical fiber make it possible to develop a new set of tools that provide deeper insights into how materials react to both strain and temperature.

One great example of this is the structural testing of full-scale aerospace structures. Thousands of fiber optic strain gauges can be installed on an aircraft in a fraction of the time required to install traditional strain gauges, making it economically feasible to collect strain measurements at thousands of sensing points.

Another one is the structural health monitoring of weight sensitive structures, such as a lightweight UAV, due to the remarkable reduction in cabling required for FOS sensors.

The contrast in cabling requirements is illustrated in Figure 1.

Figure 1: Instrumentation comparison of strain gauge and fiber optic sensing technology

Trade studies performed at NASA Armstrong Flight Research Center (NASA AFRC) show that a typical FOS installation is 0.1% to 1% the weight of a traditional foil strain gauge installation [2].

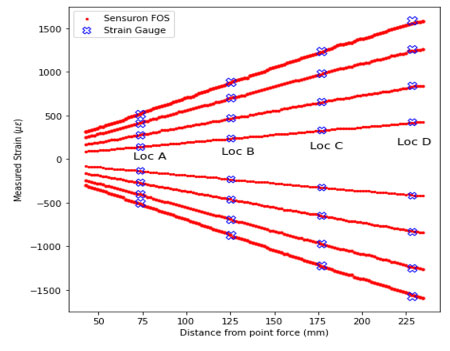

While FOS sensors have created a paradigm shift in the structural testing arena, their operation is still analogous to that of an electric strain gauge.

Instead of monitoring changes in electrical resistance, changes in reflected optical wavelength are monitored and correlated to mechanical strain via a gauge factor:

Strain gauge technology was developed nearly a century ago and has been considered the gold standard for performing experimental strain measurements for the past several decades.

However, the use of fiber optic sensing technology continues to become more prevalent as engineers increasingly take advantage of the advanced testing technologies available in the 21st century.

The primary advantages of FOS technology will be discussed in subsequent blog posts.