Riding the Wave of Innovation: Advancements in Fiber Optic Sensing Technology

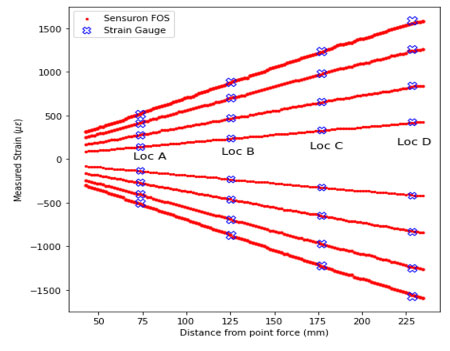

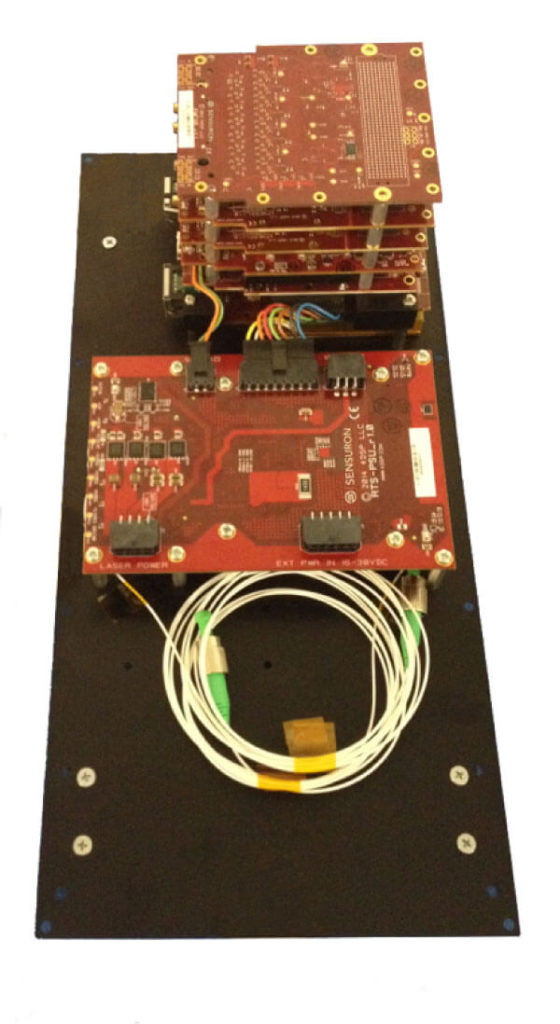

In the ever-evolving landscape of technology, one area that continues to push the boundaries of what’s possible is fiber optic sensing. The latest developments in this field are not only fascinating but also hold the promise of revolutionizing industries that rely on precise measurements. From enhancing accuracy to improving sensitivity and reliability, the strides made […]

Riding the Wave of Innovation: Advancements in Fiber Optic Sensing Technology Read More »